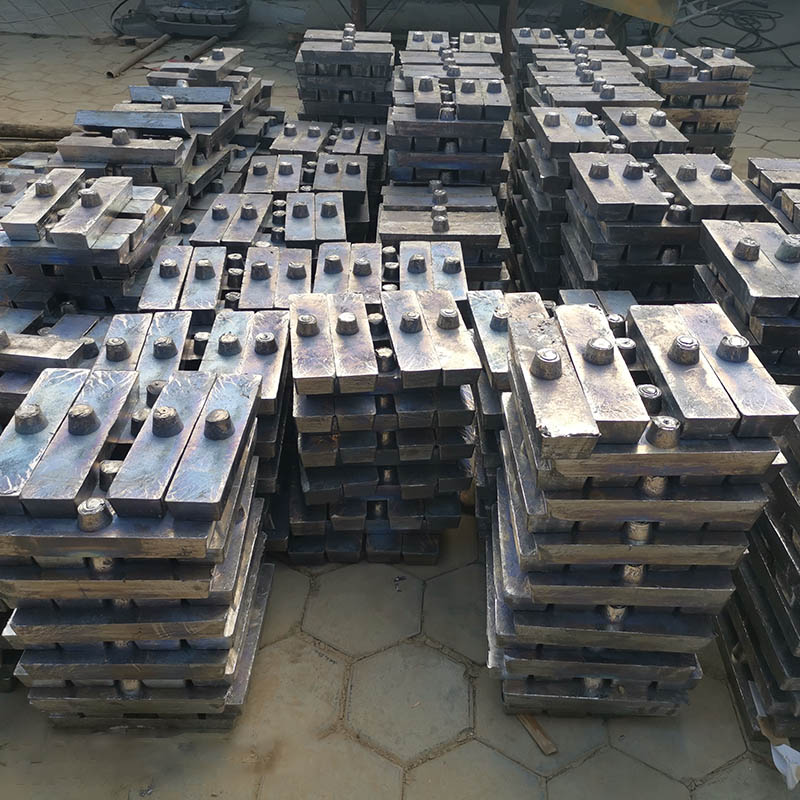

Product Display

Quality Inspection for Soldering Lead Wire - Lead Ingot Remelted High Purity 99.994% – Heru

Quality Inspection for Soldering Lead Wire - Lead Ingot Remelted High Purity 99.994% – Heru Detail:

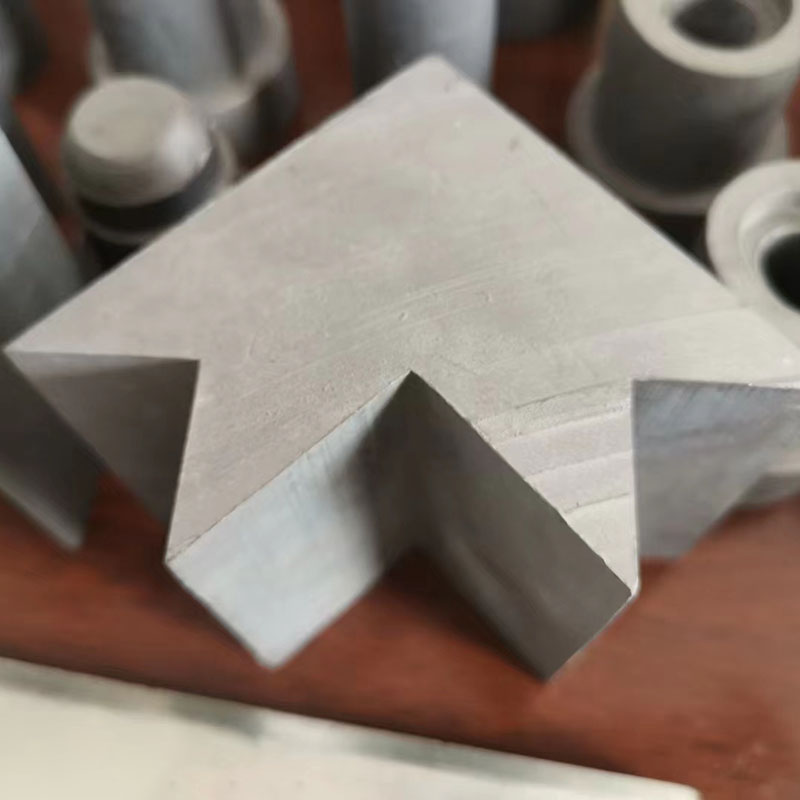

The lead ingots are rectangular in shape, with protruding ears at both ends, blue-white metal, and softer. The density is 11.34g/cm3 and the melting point is 327°C, 99.95% purity.

1. The surface of the lead ingot shall not be covered with slag, particulate oxygen, inclusions and external pollution.

2. Lead ingots must not have cold partitions, and there must be no flying edge burrs greater than 10mm (trimming is allowed).

Divided into A, B, C three categories.

Class A: Pure lead ingots, with a lead content of more than 99.994%.

Class B: containing impurities, with a lead content of more than 70%.

Class C: containing impurities, with a lead content of more than 50%.

Test method: The arbitration analysis method of the chemical composition of lead ingots is carried out in accordance with the provisions of GB/T4103 “Chemical Analysis Methods of Lead and Lead Alloys”.

Logo

1. Each lead ingot is cast or printed with the trademark and batch number.

2. The lead ingot should be marked with paint that is not easy to fall off, and the color and position of the mark should meet the requirements.

3. Each bundle of lead ingots should have a conspicuous mark that is not easy to fall off, indicating the name of the manufacturer, product name, grade, batch number and net weight.

Manufacture of batteries, coatings, warheads, welding materials, chemical lead salts, cable sheaths, bearing materials, caulking materials, babbitt alloys and X-ray protective materials.

Implement the standard: GB/T469-2005.

Mark: Lead ingots are divided into 5 marks according to chemical composition, and the most commonly used refined lead on the market is Pb99.

The single weight of small ingots can be: 48kg±3kg, 42kg±2kg, 40kg±2kg, 24kg±1kg.

The single weight of the large ingot can be: 950 kg±50 kg, 500 kg± 25 kg.

Packing: Small ingots are bundled with a non-rusty band. Large ingots are supplied as bare ingots.

1. Lead ingots should be shipped by means of transport without corrosive substances to prevent being rained.

2. Lead ingots should be stored in a ventilated, dry, non-corrosive substance inventory room.

3. In the process of transportation and storage, the white, off-white or yellow-white film generated on the surface of the lead ingot is determined by the natural oxidation properties of lead and is not used as a basis for scrapping.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for Quality Inspection for Soldering Lead Wire - Lead Ingot Remelted High Purity 99.994% – Heru , The product will supply to all over the world, such as: Lithuania, Portland, Armenia, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

.png)