Product Display

OEM Customized Electrode Lead Welding - Lead Glass Clear X Ray Radiation Protection – Heru

OEM Customized Electrode Lead Welding - Lead Glass Clear X Ray Radiation Protection – Heru Detail:

The common thickness of lead glass is 10mm 12mm 15mm 18mm 20mm.10 mm corresponds to 2 lead equivalents, 12 mm is 2.5 lead equivalents, 15 mm is 3 lead equivalents, 18 mm is 4 lead equivalents, and 20 mm is 4.5 lead equivalents.More than 20mm thick can be customized. Generally, 3-4 lead equivalents are used in CT rooms, and 2-3 lead equivalents are used in stomatological hospitals.

At present, the ZF2 lead glass and ZF3 lead glass used in China are almost the same kind, the lead equivalent and density are the same, the density is 4.2, and the light transmittance reaches about 95%, so we do not have to entangle the relationship between zf2 and zf3 lead glass, which is actually a glass.

ZF6 lead glass has the characteristics of high lead content, good protection, light weight, and is solid and durable, mainly used in nuclear power plants, atomic energy applications and other nuclear industry fields.

Lead glass is chemically stable better than pure phosphate glass. However, if the phosphate system is combined with a silicate system, a desalination system, or other systems, miscible phenomena occur immediately -7.4.3 high lead silicate glass, the color depends on the structure.High lead silicate glass is generally yellowish green. In transparent optical glass, the influence of copper or ions on glass and the change of glass structure have significant influence on the transmittance of lead glass.

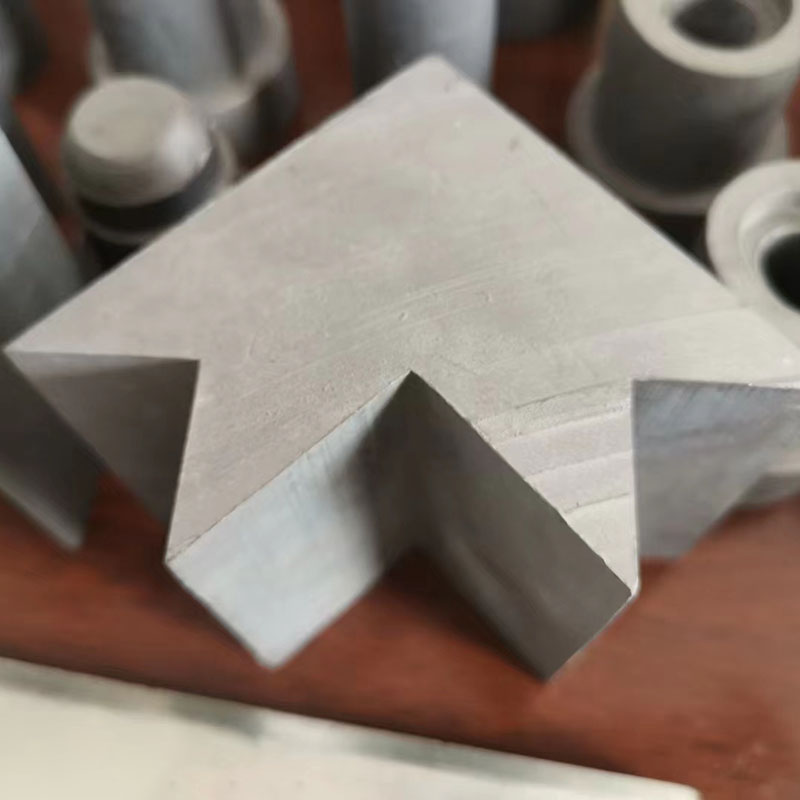

Product detail pictures:

Related Product Guide:

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for OEM Customized Electrode Lead Welding - Lead Glass Clear X Ray Radiation Protection – Heru , The product will supply to all over the world, such as: Manila, Nigeria, Grenada, We expect to deliver merchandise and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products and solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

.png)