Product Display

Leading Manufacturer for Soldering Lead With Flux - Lead Sheet Seamless 1.5mm 2mm 3mm – Heru

Leading Manufacturer for Soldering Lead With Flux - Lead Sheet Seamless 1.5mm 2mm 3mm – Heru Detail:

Therefore, it can be commonly used in acid-resistant environment construction, sound insulation, etc. It can be used in many aspects such as radiation protection, anti-corrosion, medical radiation protection, X-ray, CT room radiation protection, aggravation, sound insulation, etc. It can also be used in chemical, environmental protection, medical, nuclear power, aerospace, electroplating, machinery, military and other industries for anti-corrosion, anti-radiation material engineering. Lead door, protective door, lead protective door, X-ray protective door, ray protective lead door, medical lead door, radiation shield lead door, industrial Flaw detection lead doors, radiation protection doors, medical protective doors have a large number of stock in stock all the year round; special specifications and lead alloy materials are only 3-5 days to order.

It is the rays emitted by radioactive material that block it, not the radioactive material. α particle penetration is weak, a piece of paper can block; Lead plate can be completely blocked, protection α radiation focus do not accidentally eat, stain the skin; β rays, the penetration is medium strong, the general lead plate can block most of the rays, but usually when protecting β rays, a layer of lower atomic number blockers is added to avoid the generation of radiation. γ rays are produced with α and β and have strong penetration. A certain thickness of lead plate can block a certain proportion of strength of γ rays, radioactive intensity with the thickness of the lead plate decays according to the exponential law, theoretically can not be completely blocked. Complete blocking is also not necessary, in fact radioactivity is everywhere, and there are rays in the surrounding space. As long as it is controlled within a reasonable range.

It has the characteristics of high precision, no impurities, stable dense performance, no pores, high light transmittance, strong radiation resistance and corrosion resistance, chemical stability, high surface hardness, long service life, etc. Lead plate is also called anti-radiation lead plate, radiation protection lead plate, in addition lead plate can also be used in industrial flaw detection, acid and corrosion resistance, sound insulation, battery, industrial product counterweight, etc,In different industries, it is called flaw detection protection lead plate, sound insulation lead plate, anode lead plate, etc. The characteristics and parameters of the lead plate: the atomic weight of lead is 207, the melting point is 327°C, and the density is 11.34g/cm3. The pure lead plate is relatively soft, also known as “soft lead”. The hardness of lead-antimony alloys with antimony is greatly increased, also known as “hard lead”, and there are also lead-stilbene polyethylene sheets containing stilbene.

Manufacture of lead sheets, lead bricks, lead glass. Composite protective board and other lead products, the production of lead products are all made of lead ingots above 99.99, mainly used for hospital protection, industrial flaw detection, industrial anti-corrosion. The lead sheet specifications are 1.5 meters wide and thick, and the thickness is from 0.3mm to 50mm, mainly including: 0.5mm lead sheet, 0.6mm lead sheet, 0.7mm lead sheet, 0.8mm lead sheet, 0.9mm lead sheet, 1mm lead sheet, 1.2mm lead sheet, 1.5mm lead sheet, 2mm lead sheet, 3mm lead sheet, 4mm lead sheet, 5mm lead sheet can also be customized according to user needs.Our factory can process and manufacture lead plates, anti-radiation lead plates, lead plates and other lead alloy plates of various sizes according to customer requirements, which are suitable for chemical, environmental protection, medical, nuclear power, aerospace, electroplating, machinery, military industry And other industries for anti-corrosion, anti-radiation materials.

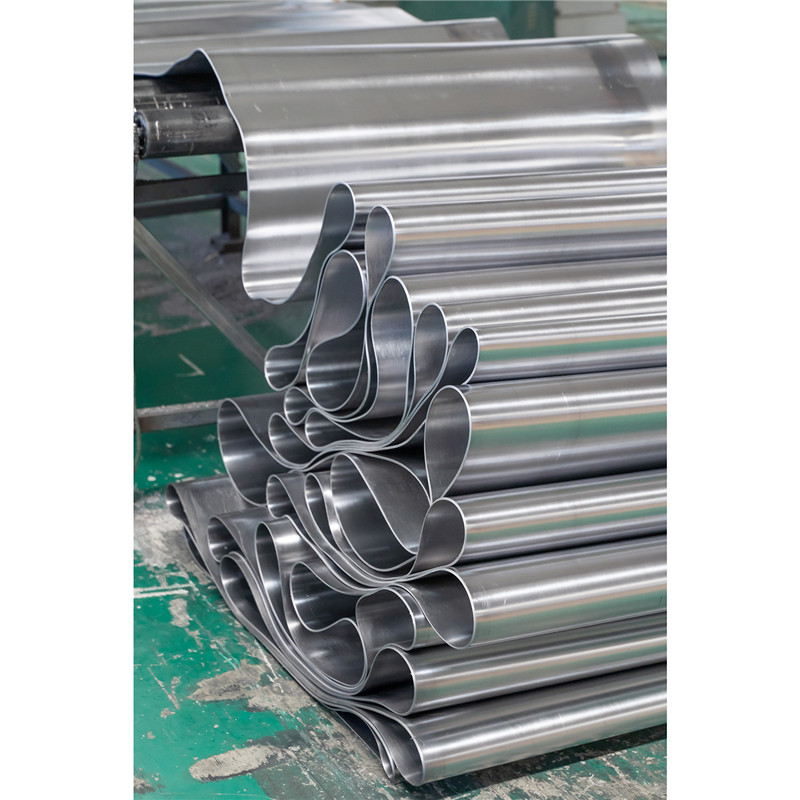

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for Leading Manufacturer for Soldering Lead With Flux - Lead Sheet Seamless 1.5mm 2mm 3mm – Heru , The product will supply to all over the world, such as: Korea, Burundi, Angola, As operation principle is "be market-oriented , good faith as principle, win-win as objective", holding on "customer first, quality assurance, service first" as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

.png)